train-detectionSerbia

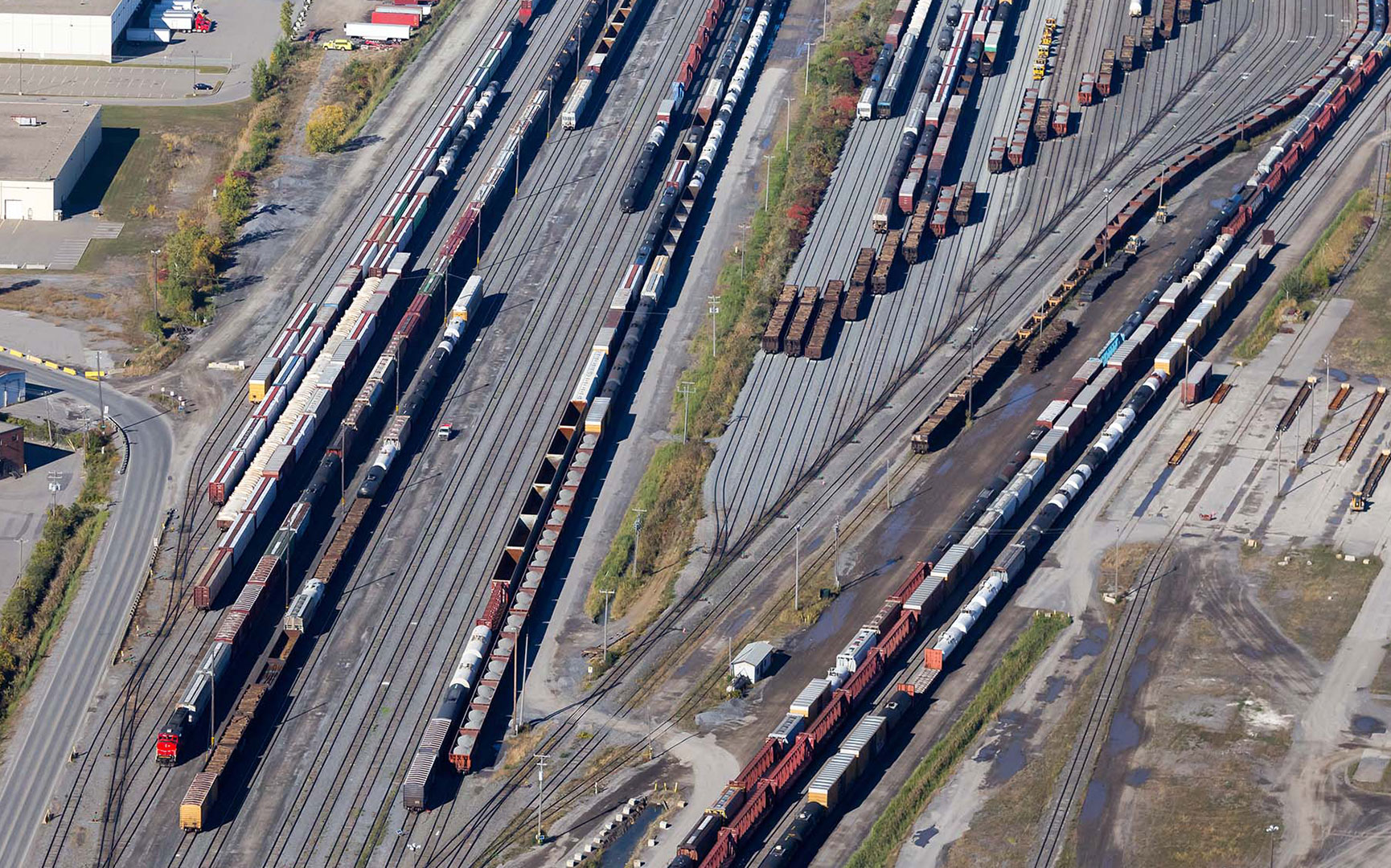

Hungary-Serbia Railway Project | Serbia

The Hungary-Serbia Railway Project is an iconic project of the “One Belt One Road” Initiative between China and CEE countries. Frauscher provides not only high-quality solutions but also detailed technical support and clarification.

The Hungary-Serbia Railway Project is an iconic project of the “One Belt One Road” Initiative between China and CEE countries. The railway runs from Belgrade, Serbia to Budapest, Hungary, spanning a total of 341.7 km. The project is taking place in Serbia. Currently, the section from Belgrade to Nov Sad has been put into operation in March 2022, with a maximum operating speed of 200km/h.

Frauscher supplied the Frauscher Advanced Counter FAdC for this project, using the Frauscher Safe Ethernet FSE protocol. The wheel sensor RSR123 installed on the trackside proves a robust ability to EMI by its V.mix Technology® patent. Its pluggable cable also makes it easier to install and replace. Both the indoor and outdoor equipment significantly speed up the installation and reduced the costs for the entire project.

The transcontinental railway requires Chinese railroad equipment that aligns with the ETCS-L2 train control system standards of Europe and the Certificate of Technical Specification for Interoperability (TSI), a new requirement for Chinese equipment in the rail signalling field.

Frauscher has cooperated with China Railway Signal & Communication Group (CRSC) for 15 years. As an Austrian brand in the Chinese market, the Frauscher China team, Austrian headquarters, and CEE team worked closely together to play an indispensable role as a link between China and Europe in the process of aligning signalling technology standards, providing technical clarification support for customers to attain the TSI certificates and Serbian country approval.

Flexible configuration options

Frauscher Advanced Counter FAdC is able to communicate with higher-level interlocking system via safety protocols, such as customized protocols and Frauscher Safety Ethernet FSE which is used in this project.

Highly resistant to electromagnetic interferences

Wheel Sensor RSR123 has a high ability to resist the EMI with its V.Mix Technology® patent. Its pluggable cable and Frauscher Rail Claw SK150 significantly reduce installation and maintenance costs.

Exhaustive technical service

Frauscher provides not only high-performance products but also detailed technology clarification and on-site training.

This might also interest you

train-detectionIndia

Jhansi - Bina Railway Line | India

train-detectionUnited States of America

Frauscher Track Vacancy System FTVS Testing | USA

train-detectionUnited States of America

MTA Baltimore North Avenue Yard | USA

train-detectionDenmark

Renewal signalling FAdC and RSR123 | Denmark