Notification Center

Meet the Frauscher Track Vacancy System FTVS – the axle counting system developed specifically for non-vital applications. FTVS is a simple and cost-effective solution that reliably supports rail operations, even in the harshest weather conditions.

The FTVS axle counter’s space-saving design, quick installation and seamless integration into existing and higher-ranking systems makes it the ideal choice for operators seeking a reliable system with minimal maintenance requirements.

Minimal space and maintenance requirements

Optimal performance in adverse weather and track conditions

Fast installation and set-up

Seamless integration into higher-ranking systems

Expandable diagnostics via wayside equipment

FTVS works hand in hand with the Wheel Sensor RSR110 – our industry tested solution for non-vital axle counting applications. To convert the analog sensor signals into digital output, the FTVS utilizes the Wheel Signal Converter WSC. The Wheel Counting Board WCB component of this cost-effective system provides information on the occupation status of certain track sections.

Like all Frauscher solutions, the FTVS works reliably under the most adverse conditions. Extreme temperatures, flooding, ice, snow, and dust have no effect on system performance. Another operator benefit is the long intervals for required maintenance, with calibration necessary just once every two years.

The FTVS axle counter can be used for a variety of applications, as a stand-alone system or as an overlay to an existing system. It can be utilized in difficult environmental conditions, including where track and ballast are deteriorated, and can be applied as a "spot fix" in problem areas. Use of the FTVS is ideal in tight spaces such as around switches, where the use of some train detection equipment is difficult.

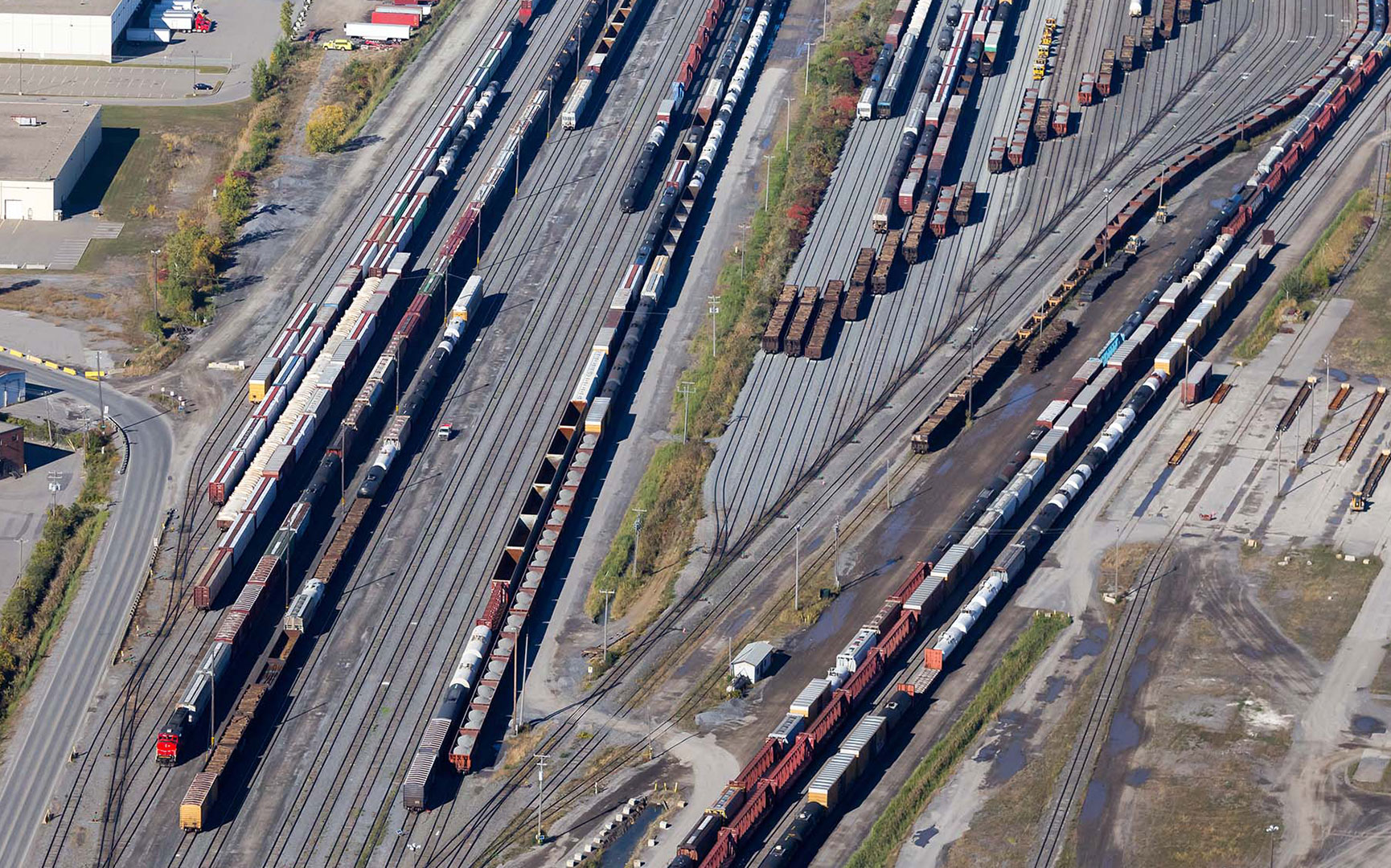

Yards

Ports

Industrial facilities

Mining

Other non-public properties

Protection of switch points

Part of an end track warning system

Provides vacancy information for storage tracks

Establishes precise fouling points

Other automation tasks

Due to its space saving DIN rail mount, the axle counter FTVS requires a small footprint in wayside enclosures, making it suitable for installation in tight spaces.

Calibration can be carried out via the Wheel Signal Converter WSC, reducing time on track for personnel and thereby increasing safety.

Reduced track time and increased safety are also achieved during installation of the sensor. It is attached to the rail in minutes, without drilling or bonds, using the Frauscher rail claw. The plug-in cable design of the Wheel Sensor RSR110 helps reduce installation time even further.

With the right equipment, FTVS also provides valuable diagnostic data. For example, local diagnostics are available via the Frauscher service display ASD – made possible by our Wheel Signal Converter WSC. Integration into higher-level diagnostic systems is also possible via this serial interface.

no preview image

The Frauscher Track Vacancy System (FTVS) is an axle counting system that is suitable for an array of non-vital applications. You can learn more about it in this video!

Read more about the development of the Frauscher Track Vacancy System which represents a cost-efficient axle counting solution, ideal for non-vital applications.

Train Detection for Yards, Ports, and Industrial Facilities with the Frauscher Track Vacancy System FTVS.

Do you require more information? Contact us - we're here for you!